[vc_row content_align_vertical=”content-vert-top” tdc_css=”eyJhbGwiOnsicGFkZGluZy10b3AiOiIxMjAiLCJwYWRkaW5nLWJvdHRvbSI6IjMwIiwiYmFja2dyb3VuZC1pbWFnZSI6InVybChcImh0dHA6Ly93d3cuaGFuZGFsY29tcHJlc3Nvci5jb20vd3AtY29udGVudC91cGxvYWRzLzIwMTgvMDkvMTQ3LmpwZ1wiKSIsImJhY2tncm91bmQtcG9zaXRpb24iOiJjZW50ZXIgY2VudGVyIiwib3BhY2l0eSI6IjAuOSIsImRpc3BsYXkiOiIifX0=” full_width=”stretch_row_1200 td-stretch-content” row_parallax=”yes”][vc_column tdc_css=”eyJhbGwiOnsibWFyZ2luLWJvdHRvbSI6IjAiLCJwYWRkaW5nLWJvdHRvbSI6IjAiLCJkaXNwbGF5IjoiIn19″][vc_empty_space height=”200px”][/vc_column][/vc_row][vc_row full_width=”stretch_row_1600 td-stretch-content” gap=”2″ tdc_css=”eyJhbGwiOnsicGFkZGluZy10b3AiOiIzMCIsImJvcmRlci1jb2xvciI6IiM4MzhhOGIiLCJiYWNrZ3JvdW5kLWltYWdlIjoidXJsKFwiaHR0cDovL3d3dy5oYW5kYWxjb21wcmVzc29yLmNvbS93cC1jb250ZW50L3VwbG9hZHMvMjAxOC8wOS9vaWwtYW5kLWdhcy1waXBlbGluZS5qcGdcIikiLCJvcGFjaXR5IjoiMC4xIiwiZGlzcGxheSI6IiJ9fQ==” content_align_vertical=”content-vert-top” row_divider_top=”” svg_background_color_top=”#838a8b” row_divider_bottom=”” svg_background_color_bottom=”#838a8b”][vc_column width=”5″][vc_raw_html]JTNDZGl2JTIwc3R5bGUlM0QlMjJtYXJnaW4tdG9wJTNBMzBweCUyMiUzRSUzQ2ltZyUyMHNyYyUzRCUyMmh0dHAlM0ElMkYlMkZ3d3cuaGFuZGFsY29tcHJlc3Nvci5jb20lMkZ3cC1jb250ZW50JTJGdXBsb2FkcyUyRjIwMTglMkYwOSUyRjU1MHg0MDBfYm9vdC0xLTIucG5nJTIyJTNFJTNDJTJGZGl2JTNFJTBBJTNDYnIlM0UlM0NiciUzRSUwQSUzQ2RpdiUzRSUzQ2ltZyUyMHNyYyUzRCUyMmh0dHAlM0ElMkYlMkZ3d3cuaGFuZGFsY29tcHJlc3Nvci5jb20lMkZ3cC1jb250ZW50JTJGdXBsb2FkcyUyRjIwMTglMkYwOSUyRjU1MHg0MDBfYm9vdC0yLnBuZyUyMiUzRSUzQyUyRmRpdiUzRQ==[/vc_raw_html][/vc_column][vc_column width=”7″][vc_column_text post_color=”#ffffff” h_color=”#ffffff” tdc_css=”eyJhbGwiOnsibWFyZ2luLXRvcCI6IjAiLCJtYXJnaW4tYm90dG9tIjoiMjUiLCJwYWRkaW5nLXRvcCI6IjMlIiwicGFkZGluZy1yaWdodCI6IjMlIiwicGFkZGluZy1ib3R0b20iOiIxJSIsInBhZGRpbmctbGVmdCI6IjMlIiwiYmFja2dyb3VuZC1jb2xvciI6IiMwMDc5OTciLCJiYWNrZ3JvdW5kLWltYWdlIjoidXJsKFwiaHR0cDovL3d3dy5oYW5kYWxjb21wcmVzc29yLmNvbS93cC1jb250ZW50L3VwbG9hZHMvMjAxOC8wOS9wZXhlbHMtcGhvdG8tMjQzMTM4LmpwZWdcIikiLCJvcGFjaXR5IjoiMC4xIiwiZGlzcGxheSI6IiJ9fQ==”]

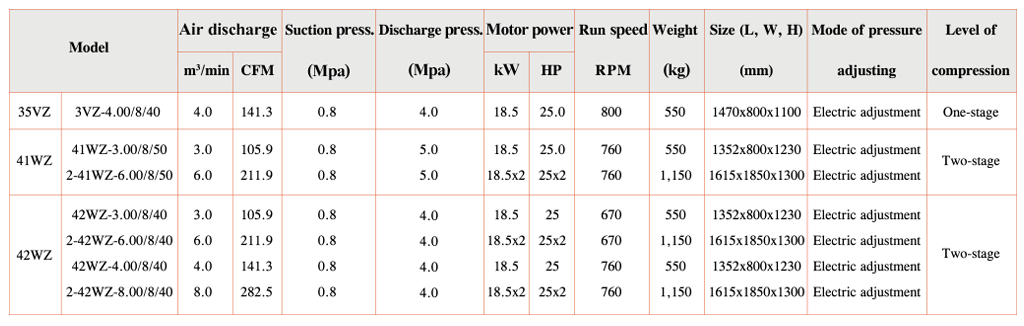

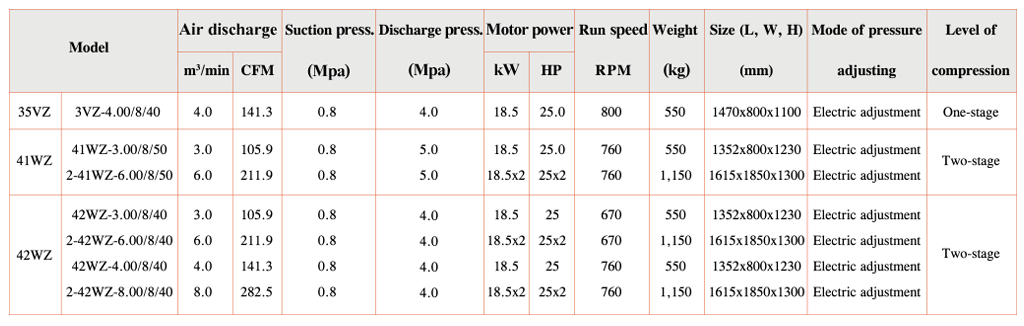

Booster Air Compressor

It is the most optimal solution for the large flow rate, medium pressure air system. it can increase the pressure form 0.8 – 1.0 Mpa air source of the user to 4.0 – 5.0 Mpa (the largest flow rate can be up to 16.0 m3/min). The low and medium pressure system is separated form each other, easy to be assembled and runs with high reliability and low cost. The low pressure system can be any type of screw units.

Main Characters of Handal Booster Air Compressor:

- Handal patent cylindrical direct-flow valve is used by our compressors. The valve is made from the stainless steel belt imported from Sweden and it is free from fracture during the working life.

- The piston of our air compressor aplies the integral cast chromium plating ring, the working life is extended by 3 to 4 times.

Handal’s unique compressor dymanic balancing technology. The vibration is only as a quarter of the world standard. - The whole air compessor adopts rolling bearing without bearing shell (Comprising connecting rod).

- To ensure safety and reliability of air compressor, redundancy design principle is adopted and multiple protection measures are taken: such as overload protection; overheat protection; phase-failure protection; undervoltage protection; drainage while stop running; startup under the condition pressure is zero.

- High reliability, long maintenance cycle, very low oil consumption (oil-saving), low energy (power saving), these dramatically reduce the general operating cost of our air compressors.

BOOSTER AIR COMPRESSOR

Sample

[/vc_column_text][/vc_column][/vc_row]